Ventilation Installations for Bomb Shelters

GENERAL DESCRIPTION

Proper provision of shelters is an urgent need for different regions of Ukraine, given the state of war and constant danger to the population.

The main task of such structures is to ensure the protection of people in the event of a threat: military, man-made, climatic etc. The shelter must be designed for the long-term stay of a significant number of people. And therefore, when arranging it sanitary conditions must be strictly observed, and first of all, properly organized ventilation.

Kyiv Fan Plant is the leader in the Ukrainian segment of ventilation systems. We specialize on the development and implementation of equipment for arranging shelters, and one of the first in Eastern Europe developed a line of electric manual fans for bomb shelters. Our industrial capacities allow us to solve problems of any complexity and create ventilation equipment of all types and types, including working ones wheels up to 4700 mm in diameter.

We offer a full range of equipment for arranging ventilation in shelters and bomb shelters according to DBN V.2.2-5:2023 “CIVIL DEFENSE PROTECTIVE STRUCTURES”.

Our ventilation systems will protect the premises from overheating, air stagnation, ingress of dust or gaseous substances from the outside. We will ensure a comfortable and safe stay of the population in shelters even during a long period of time dangers.

IMPORTANT!

Ventilation, air conditioning and heating systems of warehouses and dual-purpose facilities (DPUs) must be designed for people staying in them for 48 hours continuously. Storage rooms with two modes of ventilation – for 12 hours continuously in filter ventilation mode, and warehouses with the third ventilation mode – for 6 hours continuously in air regeneration mode.

Ventilation, air conditioning and heating systems should be designed from standard or typical elements, mainly in the form of blocks and enlarged nodes. When placing the equipment in the room, choose the most reliable ones places, taking into account possible deformations of structures due to the action of blast waves.

VENTILATION MODES

- Mode of clean ventilation (mode I) – supply to the storage and SPP of dust-free external air. Provides oxygen circulation and removal of heat and moisture from the premises.

- Filter ventilation mode (mode II) – external air, which is supplied to the storage and SPP, it is cleaned from gaseous means of mass destruction, aerosols and dust, including from combat poisonous, dangerous chemical and radioactive substances and biological agents, combustion products.

- Regeneration mode of internal air (mode III) is provided in storages and SPPs, which located in places of potential gasification of the air by products of combustion, chemical pollution or possible flooding. The need for the internal air regeneration mode (mode III) is specified in the design specification.

VENTILATION DEVICES FOR BOMB STORIES

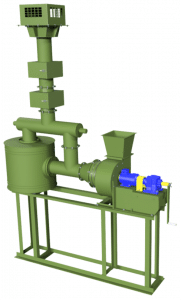

VUB-20/50 bomb shelter ventilation unit is designed to provide clean air to shelters where at the same time up to 20 people can stay for 6-48 hours, depending on the ventilation mode.

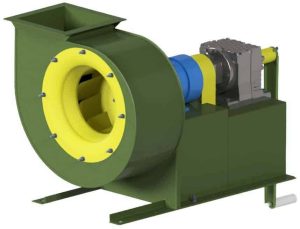

The electric fan is the main component in bomb shelter ventilation systems. The fan can work as from power grid 220/380 (depending on the electric motor), as well as from mechanical scrolling of the handle.

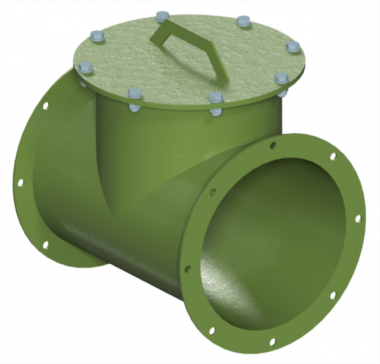

The installation has an anti-explosion protective section at the beginning of the air duct. It closes automatically under pressure blast wave and thereby protects the ventilation system from damage.

To ensure the necessary air cleanliness in the clean ventilation mode, two connected in series are used replaceable dust filters. The first one is coarse cleaning, the second one is with a cleaning factor of 0.8. The main component of the filtration system is an anti-radiation filter-absorber designed to work in the filter ventilation mode in the event of a radiation or chemical threat (additional catalysts are added at the Customer’s request).

VUB-20/50 will be the optimal solution for private houses, enterprises, suburban complexes, as well as small kindergartens and schools. If necessary, the system is completed according to the needs of the customer and is scalable.

Installation is carried out in private and basement premises, underground/semi-underground parking lots, shelters with reinforced concrete structures and cellars. You can mount the installation yourself, provided you follow the instructions.

TYPICAL EQUIPMENT USE SOLUTION

Solutions for ventilation systems with the possibility of mechanical rotation of the ERV-type fan using gear systems.

*The picture shows an example of a typical finished structure.

If required, it is possible to perform the filtering part of the structure separately from the ventilation unit, which will give the possibility of installing a protective screen between these blocks.

The main element of the ventilation system for the bomb shelter from “Kyiv Ventilatorny Zavod” LLC is ERV electric manual fan (1). It is equipped with a gear system with a handle for a mechanical one prompting the fan to work. An anti-explosion device UZS (7) is installed externally at the system inlet the air from which passes through the dust filter (3) and is supplied to the double sealed valve (4). From there, according to the ventilation mode, the air enters the filter-absorber FP (5), after which with the use of adapters and flexible inserts (6) gets to ERV type fan. A KKV flow meter valve (2) is installed on it, from which air already enters to the ventilation system of the room.

If necessary, the installation can additionally be equipped with hermetic HC valves (8), which are used to block the air flow in separate sections of one engineering network; Throttle dampers (9) to regulate the flow rate and insert hatches (10), which are necessary for maintenance of individual units or sections of the ventilation system.

MANDATORY REQUIREMENTS FOR THE VENTILATION SYSTEM OF BOMB STORAGE

- In the ventilation systems of warehouses and SPP, fans with an electric manual drive should be provided. Productivity and the pressure of electric manual fans must correspond to the calculated ventilation parameters.

- The storage ventilation system and SPP are designed with at least two modes of operation: clean ventilation (mode I) and filter ventilation (mode II).

- Air ducts of supply and exhaust systems, which are laid outside, are made of building structures, designed for the action of an air shock wave, or mounted from welded steel pipes.

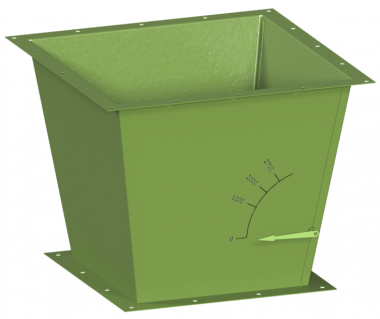

- On air intakes and exhaust devices of protective structures and SPP, installation of anti-explosion devices should be provided devices.

- Explosion-proof devices are placed within protective structures (dual-purpose structures) with provision free access to them for inspection, replacement or repair.

- In storage for inspection and cleaning of hermetic valves installed inside air ducts passing through the sealing zone, on the side of the internal premises, a hatch-insert is provided, which is installed after hermetic valve (in the direction of air movement).

- For taking air samples and taking other indicators during commissioning and testing the tightness of the system on the ventilation ducts before and after the filters, thermovalves, and fans should be checked provide welded fittings with plugs on the thread.

- Cleaning of supply air from solid particles and dust by installation must be provided coarse air purification filters.

- All ventilation openings are equipped with anti-dust devices.

- Air purifiers used to organize ventilation of warehouses and SPPs must meet the requirements DSTU 9077.