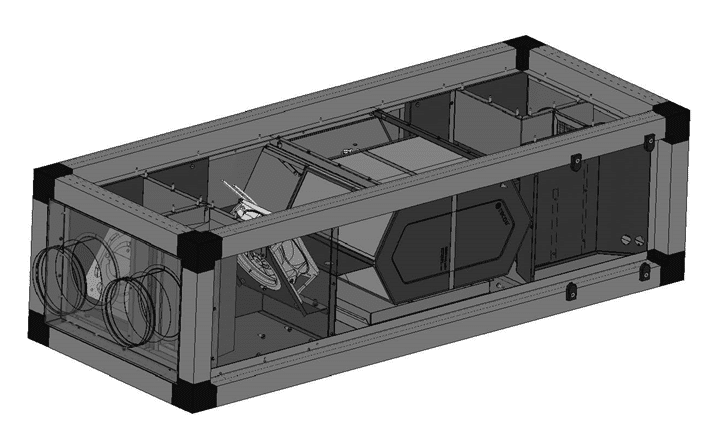

Suspended installations

| МНС 0150 | МНС 0130 | МНС 0100 | МНС 060 | МНС 035 | |||

|---|---|---|---|---|---|---|---|

| ID | МНС 0150 | МНС 0130 | МНС 0100 | МНС 060 | МНС 035 | ||

| Price, UAH | N/A | N/A | N/A | N/A | N/A | ||

| Rotation frequency, rpm | 3250 | 3500 | 2480 | 2810 | 3930 | ||

| Engine protection degree | IP44 | IP44 | IP44 | IP44 | IP44 | ||

FAN

The systems use centrifugal fans with shaft-mounted motors (EC fans). All fans are manufactured by ZIEHL-ABEGG (Germany) and EBM PAPST (Germany).

EC-technology is an intelligent technology that uses an integrated electronic control system, allowing the motor to always operate with optimal load. Compared to AC motors, EC motors have significantly higher energy efficiency. The advantage of EC fans is their low energy consumption and ease of control.

ADVANTAGES:

- High efficiency (93%), energy savings, leading to reduced operating costs (a 30% reduction in electricity costs by optimizing the fan’s operating mode based on required parameters).

- Low noise level with comparatively high power (lower by 20–30 dB(A) than traditional fans).

- Ability to smoothly and precisely adjust, with programming options, and adjust fan performance depending on temperature, pressure, and air pollution levels.

- Protection of the motor from mechanical impacts and electrical loads (the permissible input voltage range is 200-277 V and 380-480 V ±15%).

- Requires no maintenance.

- Long service life (more than 60,000 hours, or 6-8 years of continuous operation).

ENERGY RECOVERY UNIT

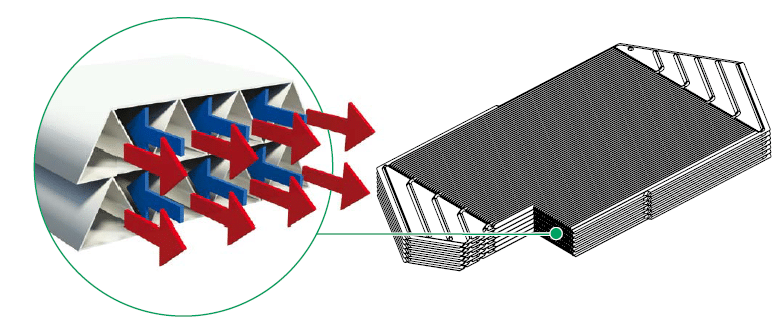

The systems use highly efficient counterflow plate heat exchangers. The plates are made from corrosion-resistant alloyed aluminum or polystyrene, which can be used at low temperatures and restores its geometry in case of frosting.

The streams of incoming fresh air and outgoing exhaust air are fully separated and directed in opposing flows along thin, parallel-aligned aluminum/polystyrene plates. The transfer of moisture and odors from one flow to another is excluded.

The efficiency of the counterflow heat exchanger can reach up to 85-90% (depending on the temperature and humidity characteristics of the intake and exhaust air).

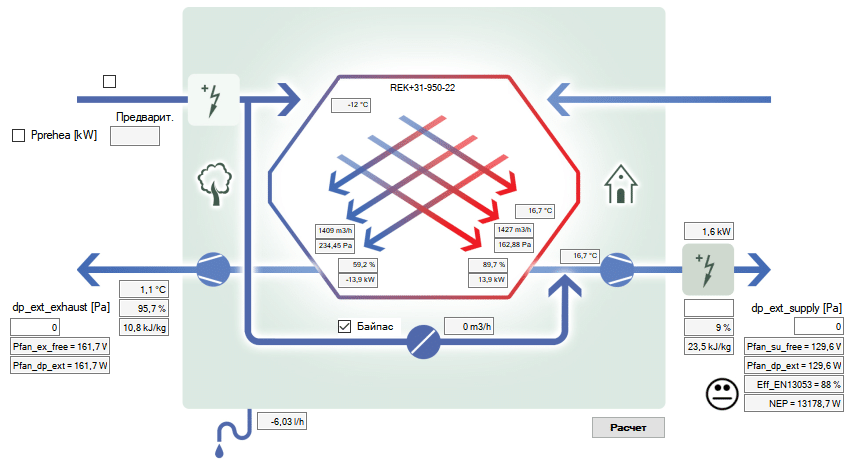

Below is an example calculation of the counterflow heat exchanger, where you can see that at an outside temperature of -10 to -12 °C, it does not freeze and has an efficiency of 88% (heating the outside air from -12 °C to +16.7 °C).

The counterflow heat exchanger module is equipped with a stainless steel drain pan.

When condensation occurs, there is a risk of the heat exchanger freezing. To prevent this, the unit is equipped with a bypass with an air valve and drive. This bypass also allows it to be used in the free-cooling mode – cooling the indoor air with colder outdoor air. This is very convenient for rooms with many internal heat loads, such as cafes, restaurants, conference halls…

ELECTRIC HEATER

The electric heater consists of a heating element made of heat-resistant Cr-Ni-Fe alloy, mounted on a frame made of steel with an AlZn coating. The heater is equipped with two overheat protection systems.

The power of the heating elements can be adjusted either with ON/OFF switches or smoothly with a triac controller.

HEAT EXCHANGERS

Water Heater/Cooler

Heat exchangers with copper tubes and aluminum fins are used. To prevent electrochemical corrosion, all collectors of the heat exchangers are made of copper. The maximum heat carrier temperature is 100 °C. The maximum working pressure is 1.6 MPa.

Additionally, the cooler is equipped with a droplet separator and a stainless steel drain pan.

Heat exchangers have fittings for drainage and flushing.

Freon Heater/Cooler

Heat exchangers with copper tubes and aluminum fins are used. The maximum working pressure is 4.2 MPa.

Additionally, the heat exchanger is equipped with a droplet separator and a stainless steel drain pan.

Freon heat exchangers are under excess pressure (nitrogen).

FILTER

Standard filters are pocket/panel filters of EU4 class, made of non-combustible, moisture-resistant synthetic fabric. The recommended final pressure drop is 200…250 Pa.

Units can also be equipped with additional air filtration systems of F7 and F9 classes, which consist of separate sections or filter boxes.

NOISE SUPPRESSORS

All units can be equipped with duct noise suppressors to meet stricter noise level requirements in the rooms served by these units.

AUTOMATION SYSTEM

The automation unit is located directly on the ventilation unit and is equipped with a remote control panel that displays all the technological parameters. The control panel connects to the automation unit with a cable of up to 100 meters in length. This allows the panel to be installed in the room serviced by the engineering system.

The ventilation unit can be turned on/off from the control panel or according to a preset schedule. The unit is also turned off if the fire alarm is triggered.

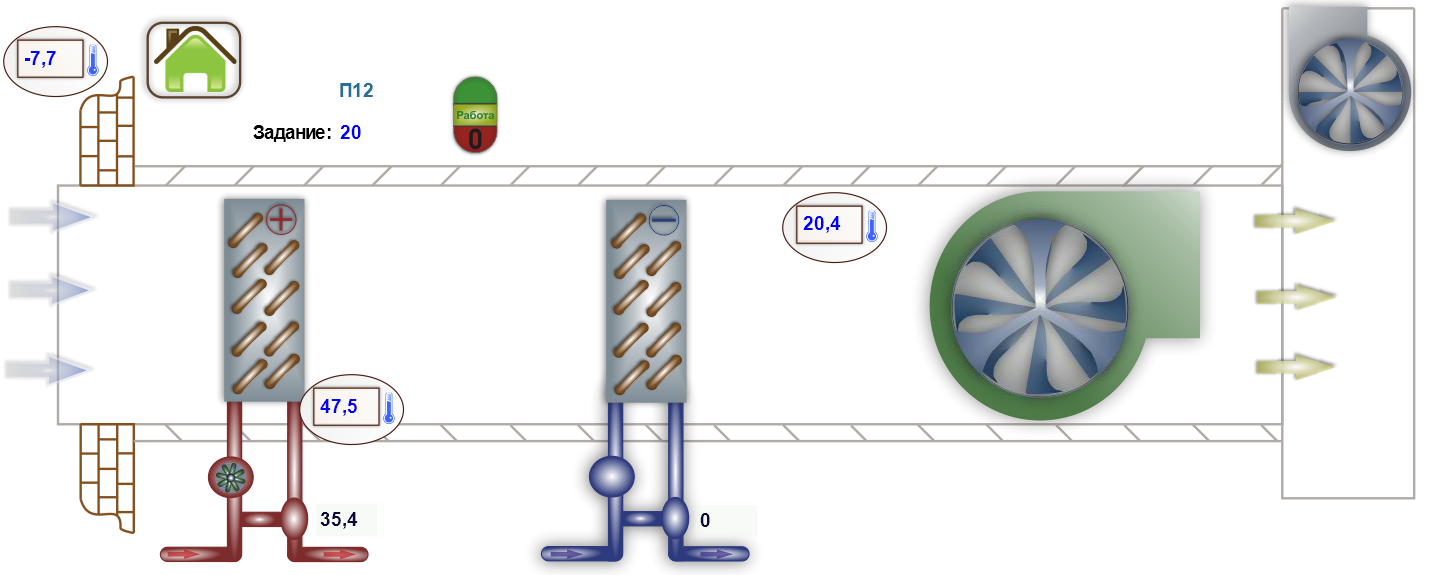

The task of the automation system is to maintain a set exhaust air temperature. At the same time, the intake air temperature is restricted by a minimum and maximum value. The system can also switch to a mode that maintains the intake air temperature.

The operation of the heat recovery unit is controlled by setting a frost thermostat on the exhaust air. If the thermostat is triggered, the defrosting process begins by opening the bypass valve.

The ventilation units have smooth fan speed regulation. The intake and exhaust fan speeds change synchronously. There is also a speed control mode where the speed decreases when the set temperature is reached in the exhaust duct.

The automation system, in its standard configuration, allows connection to a dispatch system using the MODBUS protocol. The automation system’s manual includes a list of variables needed for this connection.

DISPATCHING SYSTEM

Dispatching is not included in the basic package of the unit. If remote monitoring, control, and parameter management are needed, the customer is offered an optional package. Using this additional package, a unified SCADA system for the facility can be created along with other equipment or an individual SCADA system for managing and monitoring a specific unit.

Below is the structural diagram of the WEB-oriented dispatching system.

Using special hardware and software, remote monitoring, control, and parameter management are possible via a computer browser or mobile devices (phone, tablet). It is also possible to organize a full operator’s station with specialized software installed.

Below is an example of a mnemonic diagram of the unit in the dispatching system.